Color Coated Steel Roofings Sheets

ROOFING SHEETS

Roofing sheets are produced from a scope of materials, each known for their shifting properties and applications on various sorts of rooftops. Picking the right rooftop sheet can expand the life span and sturdiness of your rooftop. There are various sorts of roofing sheets each with exceptional structure, benefits and applications, every one of them are clarified beneath.

AC ROOFING SHEETS

AC sheets are basically imperishable and require zero support! They've been demonstrated to be the most simple to-introduce, solid and strong roofing material for stockrooms, industrial facilities, minimal expense lodging, and basically, any design requiring a rooftop.

FRP/ GRP ROOFING SHEETS

Fiberglass profiles are a practical option in contrast to conventional materials like cement, steel, aluminium and lumber. Though these materials have just a single essential strength, GRP consolidates a few benefits. This makes fiberglass ideal for the maintainable development of things to come.

CORRUGATED ROOFING SHEETS

Corrugated roofing is profoundly strong and it is a direct result of its shape. These sheets need the help strips to balance out the material since the screws for affixing do go through the pinnacle of the ribs. The curve of the ribs and valleys keeps the screws from fixing enough in the valleys.

PVC ROOFING SHEETS

PVC is impervious to enduring, substance spoiling, consumption, shock and scraped area. It is along these lines the favoured decision for a wide range of long-life and open air items. Truth be told, medium and long haul applications represent exactly 85% of PVC creation in the structure and development area.

GI ROOFING SHEETS

The GI covering has a remarkable metallurgical design and gives security against any scraped area, or mechanical harm that might happen during transportation, erection and administration. GI roofing sheets are fitting in giving programmed assurance to any harmed space of the sheet.

POLYCARBONATE ROOFING SHEETS

Polycarbonate material sheets are accessible in an assortment of characteristics and thicknesses. They are significantly lighter in weight, yet strong, and impenetrable to breakage and breaks. They can be effortlessly taken care of and can be fixed with the assistance of screws and backing bars, or can be effectively welded.

CORRUGATED POLYCARBONATE ROOFING SHEETS

Corrugated polycarbonate material sheets are accessible in a scope of decisions for light transmission and have heat proof properties. These material sheets are made with exact details to track down an able use in modern rooftop light and sunlight cladding.

METAL ROOFING SHEETS

Metal roofing sheets are well-known choice really incredible protecting properties. They are made of Zinc, Aluminium, Copper and Tin. Metal roofing gives many benefits, including the capacity to withstand almost any sort of climate condition.

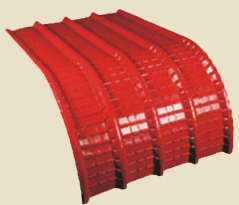

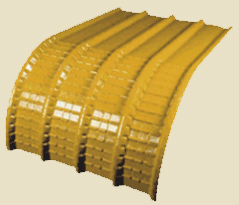

COLOUR COATED ROOFING SHEETS

Most shading covered sheets are made of Aluminium and it is one the lightest accessible business metals with a thickness of just 33% of steel or copper. When presented to air, aluminium sheets foster a slight layer of aluminium oxide.

BITUMEN ROOF SHEETS

Bituminous rooftop sheets are intended to secure private and business structures. As the name construes, these are layering that shows up at the site as rolls.

This type of trapezoidal profile has been designed in such a way by bending the front part of the profile to certain radius such as bending portion radius in end curve roofing system:

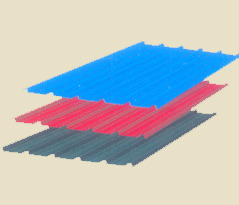

| MATERIAL | PPGI | PPGL |

| Chemical Combination | Zinc Coating Z 90 ∽ 120 |

Alu-Zinc coating AZ 70 ∽ 150 |

| Paint Coating | Reqular Modified Polyester (RMP) |

Reqular Modified Polyester (RMP) |

| Paint Thickness (Top) | 18 ∽ 20 Microns | 18 ∽ 20 Microns |

| Paint Thickness (Bottom) | 5 ∽ 7 Microns | 5 ∽ 7 Microns |

| Tensile Strength | 300Mps | 300 ∽550 Mpa |

| Thickness | 0.35mm∽0.60mm | 0.35mm∽0.60mm |

Roofing Sheet Dealers in Chennai

Roofing Sheet Dealers in Madurai

Roofing Sheet Suppliers in Chennai

Roofing Sheet Suppliers in Madurai

Roofing Sheet Manufacturers in Chennai

Roofing Sheet Manufacturers in Madurai

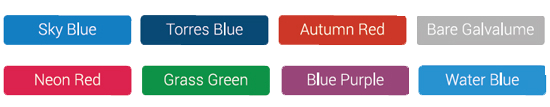

Color Range

Customized Colours

Note: Actual Sheet's Colour may vary from the above colour range. Please refer samples, while ordering. Customized colours also available for bulk quantity.